Based on 30+ years as an independent limited company contractor including involvement / specification of:

· Process Measurement Technology

· Pressure / Flow / Temp / Level / Others

· Control Valves / On-Off / ESD Valves

· Analyzer Sampling and Cond. Systems

· Installation Details / Winterization

· Drafting and CADD Standards

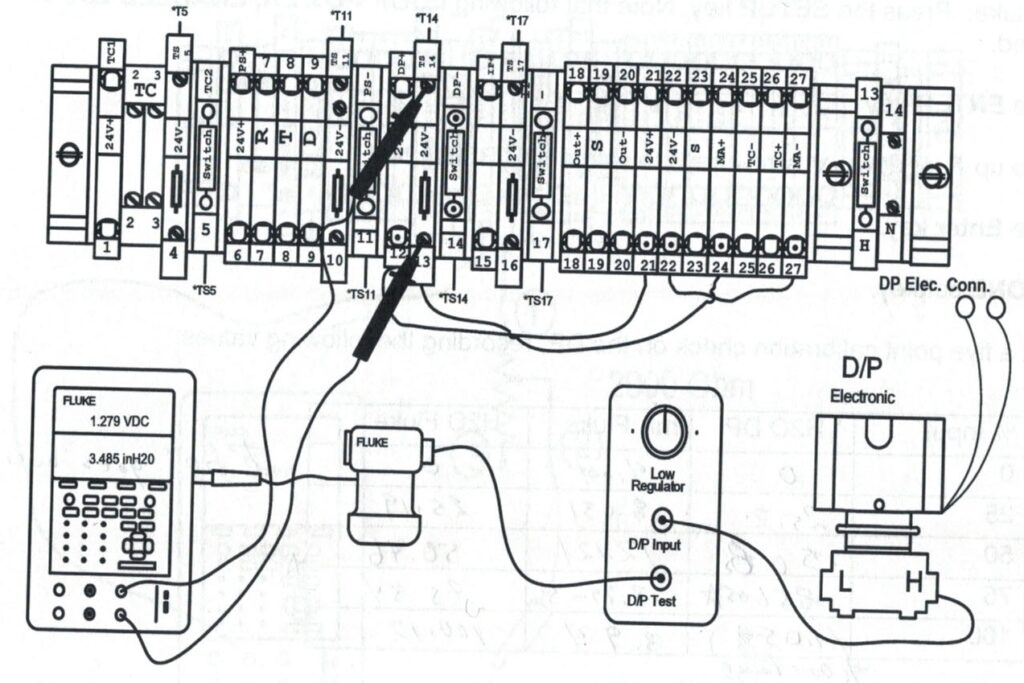

· Design Wiring

· Design Loop Wiring

· I&C Construction Turnover Support

· Calibration and Reporting Frequency

Procuring Instrument Data Sheets (Primary Element Sizing, Final Control Element Sizing), Bill of Materials, Instrumentation Drawing Schedule, P&ID and Instrument Index (SmartPlant ® Instrumentation – InTools and MS Access to native Excel format for Index, Data Sheets and Calibration Reporting) preparation in accordance with your chosen project procedures and establishing a well defined work package (EWP leading to CWP). Prepare loop wiring (CADD, SPI Enhanced, 2D layouts, JB, Cable Etc.), I/O schematics, assignment and interconnecting network topology (BPCS, FGS & ESD) to the client’s desired Control System Architecture. Ensure that all instrument and control installations meet service conditions and calibration procedures are followed, adhering to safety and quality (ISO compliant).

Applying skills and experience for the complete configuration of SMART digital process instrumentation (including Foundation Fieldbus® and ProfiBus® technologies) that increases diagnostics for effectively predicting failures while meeting all of your process control requirements.

An excellent understanding of P&ID’s and loop diagrams for correctly specifying all of your I&C automation needs for conventional SMART instrumentation (HART) with installation and maintenance turnover based on a plan for a phased early works to commissioning execution supporting CSU teams.

All feedback and inquiries are welcome…

Please tell us where we can be of assistance to your operations or you can feedback to us regarding any of our services. Call to Action